-

IMPIANTI INTEGRATI DI FORGIATURA

Realizzazione di progetti innovativi con uno sguardo al futuro, trasformando in realtà soluzioni personalizzate e sostenibili per il cliente -

REVAMPING

Ricondizionamento e up-grading -

Macchine per la forgiatura libera

Soluzioni personalizzate e affidabili -

RADDRIZZATURA AUTOMATICA

la rettilineità a portata di mano -

LAVORAZIONI MECCANICHE

tornitura, fresatura, controlli dimensionali -

PRESSE SETTORE LEGNO

presse per stampaggio e curvatura

Le nostre principali aree di produzione

Officine Meccaniche Vecchiato

L’azienda Vecchiato Officine Meccaniche Srl opera nel settore metalmeccanico dal 1977. La sua principale attività è la progettazione e costruzione di presse per l’industria del legno e per la forgiatura.

Siamo in grado di soddisfare svariate esigenze di forniture, nel campo della costruzione di macchine, ricambistica e impiantistica industriale.

Siamo in grado di soddisfare svariate esigenze di forniture, nel campo della costruzione di macchine, ricambistica e impiantistica industriale.

La Vision

Diventare un’azienda leader, nel mondo, nel settore degli impianti per forgiatura. Creare valore dalle idee e dalle abilità delle persone, contribuendo alla loro crescita, salute e benessere

Mission

Realizzare impianti innovativi che soddisfino le esigenze produttive del cliente in modo efficiente e sostenibile, con elevati standard di qualità e affidabilità.

Work Process

1

PROGETTAZIONE

Progettiamo i prodotti su misura in relazione alle vostre richieste.

2

SVILUPPO

Costruzione dei macchinari raggiungendo la massima qualità sul mercato.

3

INSTALLAZIONE

Installazione ed avviamento presso gli stabilimenti del cliente.

4

assistenza

Collaudo finale ed assistenza personalizzata.

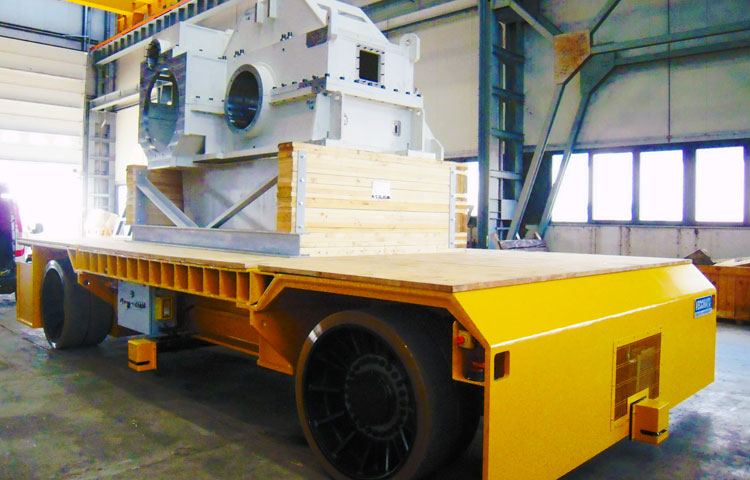

Ultimi Progetti

Via degli Olmi 9

33050 - Gonars (UD), Italia

33050 - Gonars (UD), Italia

+39 0432 992611Lun-Ven, dalle 9 alle 18

info@omvecchiato.itDi norma rispondiamo entro 24h

Scrivici

se vuoi informazioni aggiuntive.